Wiring lights to a golf cart might seem like a straightforward task, but when you’re dealing with different voltages, it becomes a bit more intricate. Golf carts, primarily designed for traversing the greens, have evolved into versatile vehicles used in various settings, from gated communities to large campuses. As their use diversifies, so does the need for enhanced features like proper lighting.

Whether you’re looking to improve visibility for those twilight rounds of golf or simply want to ensure a safer ride back home in your community, understanding how to wire 12 volt lights to a 36 volt golf cart is essential. The procedure is basically the same for 48 volt systems. This comprehensive guide delves into the nuances of this process, offering step-by-step instructions, key takeaways, and essential safety tips. No matter if you’re a seasoned golf cart owner or a newbie, this article aims to shed light on this electrifying topic.

Key Takeaways

- Understanding the golf cart’s electrical system is crucial.

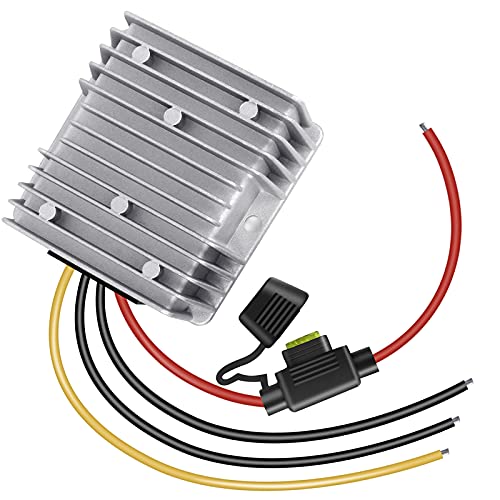

- A voltage reducer is essential when wiring 12-volt lights to a 36-volt golf cart.

- Regular maintenance and checks can prolong the life of the golf cart batteries and ensure efficient operation.

- Safety should always be a top priority during the wiring process.

12 Volt Battery and 36 Volt Golf Cart Battery Bank

Understanding the intricacies of a golf cart‘s electrical system is crucial, especially when dealing with different voltages. Most golf carts operate on 36-volt or 48-volt systems. However, many accessories, like 12-volt lights, are designed for standard automotive use. To wire a 12-volt light to a 36-volt golf cart, one must consider the voltage difference.

The voltage reducer plays a pivotal role in this process. It essentially takes the 36 volts from the golf cart‘s battery and reduces it to 12 volts, ensuring the light operates correctly without being overpowered. In some setups, a rectifier might be used as part of the voltage reduction process to ensure consistent and safe power delivery to the 12-volt lights. This is especially important as connecting a 12-volt light directly to a 36-volt system without a reducer or rectifier can damage the light

Golf cart batteries come in various voltages, including 6-volt batteries, 8-volt batteries, and 12-volt batteries. The total voltage of the golf cart is determined by the number and type of batteries installed. For instance, a 36-volt golf cart might have six direct current 6-volt batteries. When wiring, it’s essential to identify the positive terminal and negative terminal of the battery bank to ensure correct connections. The fuse is on the positive side of the circuit.

Importance of Understanding Your Golf Cart’s Battery Voltage

The voltage of your golf cart determines its power and runtime. A 36-volt golf cart typically has more extended range than a 12-volt model. Understanding this helps in ensuring that any additions, like lights, are compatible with the cart’s system.

Difference Between 12-Volt and 36-Volt Golf Cart Batteries

A 12-volt battery system usually provides enough power for a car’s electrical components such as the headlights, radio, and ignition system. On the other hand, a 36-volt battery system in a golf cart can offer extended ride times and improved performance, especially on challenging terrains. Larger battery systems are also used in electric vehicles and other heavy-duty applications where more power is needed. The choice between a 12-volt and a 36-volt battery system depends largely on the type of vehicle or device and its specific power supply requirements. Therefore, understanding the power needs of a vehicle or device is crucial in choosing the right battery system.

Preparing for the Process

Before diving into the wiring process, preparation is key. First, ensure the golf cart is in a safe state, either in park or neutral. This prevents any accidental movements. For added safety, placing bricks or blocks behind and in front of the wheels can further secure the cart.

Next, locate the golf cart batteries. These are typically found under the seat but can vary based on the cart model. It’s crucial to disconnect the battery terminals to prevent any electrical mishaps during the wiring process. Always start by disconnecting the negative terminal before the positive terminal to minimize the risk of sparks or short circuits.

Gathering the necessary tools and items beforehand can streamline the installation process. This includes a mounting kit, screwdriver kit, drill, and possibly a voltmeter to test connections.

Importance of Safety

Safety should always be the top priority. Ensuring the golf cart is stable and the batteries are disconnected can prevent accidents. Using tools correctly and following guidelines can also reduce risks.

Moreover, it is essential to always wear the appropriate safety gear when working on a golf cart. This includes gloves, safety glasses, and sturdy footwear. Always work in a well-ventilated area to avoid inhaling harmful fumes, especially when dealing with the batteries. If you’re not familiar with a certain repair or maintenance procedure, do not hesitate to seek professional help. Overlooking minor issues or attempting to fix them without proper knowledge can lead to serious problems in the long run. Regular maintenance checks and inspections can also help identify potential issues early on, preventing accidents and ensuring the longevity of the golf cart.

Tools and Items Needed for Installation

Having the right tools on hand can make the installation process smoother. This includes screwdrivers, drills, and a voltmeter. A mounting kit specifically designed for your golf cart model can also be beneficial.

Clean Golf Cart Batteries and Corrosion

Over time, golf cart batteries can accumulate dirt, debris, and corrosion. This can impede the flow of electricity and reduce the efficiency of the battery. Before starting the wiring process, it’s essential to inspect the battery terminals for any signs of corrosion.

A mixture of baking soda and water can be an effective solution for cleaning battery terminals. This mixture can neutralize the acid and remove corrosion. After cleaning, ensure the battery terminals are dry before reconnecting any wires.

Regular battery maintenance can prolong the life of the battery and ensure the golf cart operates at peak efficiency. This includes checking the water level in the battery cells and topping up with distilled water if needed.

Checking for Corrosion on Battery Terminals

Corrosion on battery terminals or ground wires can impede the flow of electricity. Regularly inspecting and cleaning the terminals can ensure a stable connection and prolong the battery’s life.

Using Baking Soda and Water for Cleaning

A mixture of baking soda and water can effectively remove corrosion from battery terminals. This neutralizes the acid and cleans the terminals, ensuring a good connection.

Mounting the 12 Volt Lights to a 36 Volt Golf Cart

Choosing the right spot to mount the 12-volt light kit on the golf cart is crucial. The placement affects the illumination and appearance of the cart. Common spots include the front for headlights and the rear for taillights. Some golf cart models come with pre-drilled holes, making the mounting process more straightforward.

Mounting kits can simplify the installation process. These kits often include brackets, screws, and other necessary hardware. If your cart doesn’t have pre-drilled holes, a drill will be required to create mounting points.

Once the golf cart lights are mounted, the wiring process can begin. This requires you to cable the lights to the golf cart’s battery or voltage reducer.

Deciding the Placement of Headlights and Taillights

The placement of the lights affects the cart’s illumination. Headlights are typically mounted on the front, while taillights go on the rear. Proper placement ensures optimal visibility.

Using Mounting Kits for Ease of Installation

Mounting kits provide all the necessary hardware for installation. This includes brackets, screws, and sometimes even wiring. Using a kit tailored for your cart model can make the process smoother.

Wiring and Battery Terminal Connections

Once the lights are mounted, the next step is the wiring process. This involves connecting the 12v lights to the golf cart’s 36-volt system. A voltage reducer is essential in this process. It takes the 36 volts from the golf cart and reduces it to 12 volts, ensuring the lights operate correctly.

The lights harness is then connected to the voltage reducer. It’s crucial to ensure the positive wire from the lights connects to the positive terminal of the voltage reducer and the negative wire to the negative terminal.

For those who don’t have a switch, the lights can be wired directly to the battery. However, having a switch allows for better control, enabling the lights to be turned on or off as needed.

Attaching the Lights Harness and Importance of a 36-Volt-12-Volt-Reducer

The lights harness connects the lights to the golf cart’s electrical system. The 36-volt-12-volt-reducer is crucial as it ensures the 12-volt lights receive the correct voltage, preventing any damage.

Connecting the Lights to the Battery: Steps and Precautions

When connecting the lights to the battery, it’s essential to ensure the positive wire connects to the positive terminal and the negative wire to the negative terminal. Using a voltmeter can help verify the connections.

Battery Maintenance and Water Level

Maintaining the golf cart batteries is crucial for the cart’s overall performance. This includes regularly checking the water level in the battery cells. If the water level is low, it should be topped up with distilled water. Avoid overfilling as this can lead to acid spillage.

The battery acid level is also essential. If the acid level is too low, it can affect the battery’s performance and lifespan. Regularly checking and maintaining the battery ensures the golf cart operates efficiently.

Checking the Water Level in Battery Cells

Regularly checking the water level in the battery cells ensures the battery operates efficiently. If the level is low, top it up with distilled water.

Ensuring the Battery Acid is at the Right Level

The battery acid level is crucial for the battery’s performance. Regular checks and maintenance can prolong the battery’s life and ensure the golf cart operates at peak efficiency.

Testing and Finishing Up

After the wiring process, it’s essential to test the lights to ensure they operate correctly. This involves reconnecting the battery terminals and using the switch to turn on the lights. If the lights don’t turn on, recheck the wiring connections.

Addressing any issues or complications during the wiring process is crucial. This ensures the lights operate correctly and safely. Regular checks and maintenance can prevent any future issues.

Reconnecting All Battery Terminals

Once the wiring process is complete, the battery terminals should be reconnected. Always connect the positive terminal first, followed by the negative terminal.

Testing the Lights Using the Switch

After reconnecting the battery terminals, use the switch to test the lights. If the lights operate correctly, the wiring process was successful.

Final Thoughts

Wiring 12-volt lights to a 36-volt golf cart might seem challenging, but with the right tools and guidance, it’s a straightforward process. The key is understanding the golf cart’s electrical system and using a voltage reducer to ensure the lights receive the correct voltage. Regular maintenance and checks can ensure the lights and golf cart operate efficiently.

Leave a Reply