The Harley Davidson Golf Cart Wiring Diagrams 1963 To 1966 provide a straightforward testing procedure requiring only a few basic tools…

Basic Circuit Operation

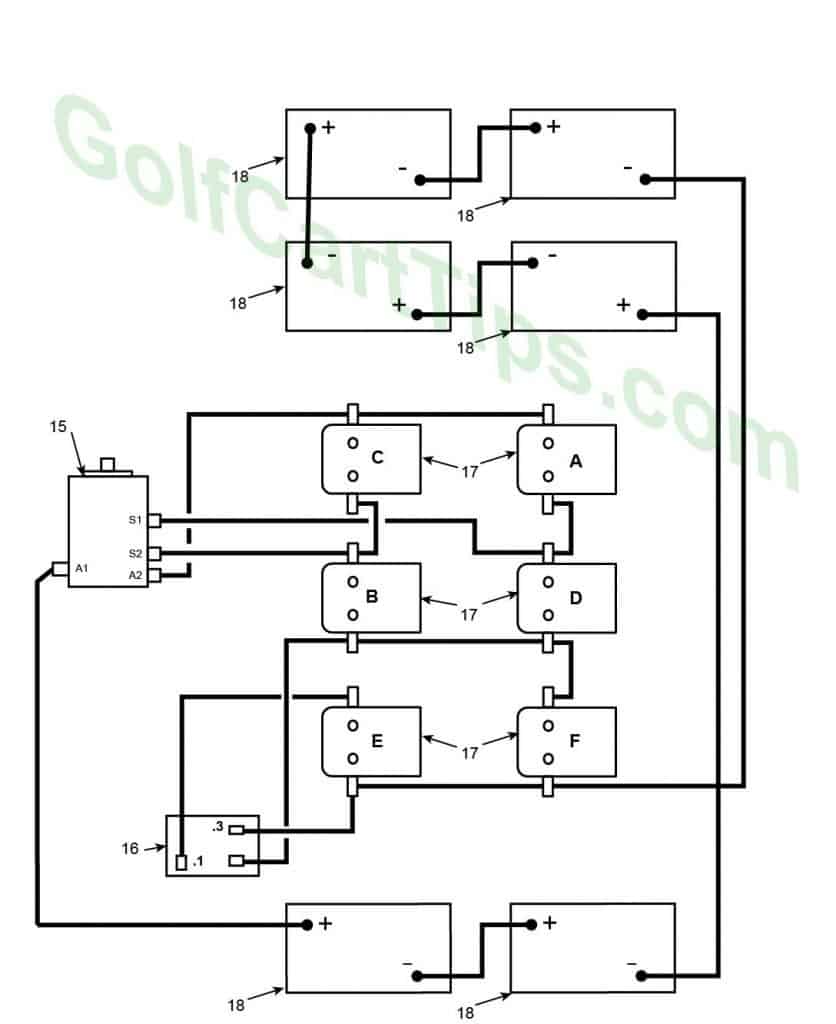

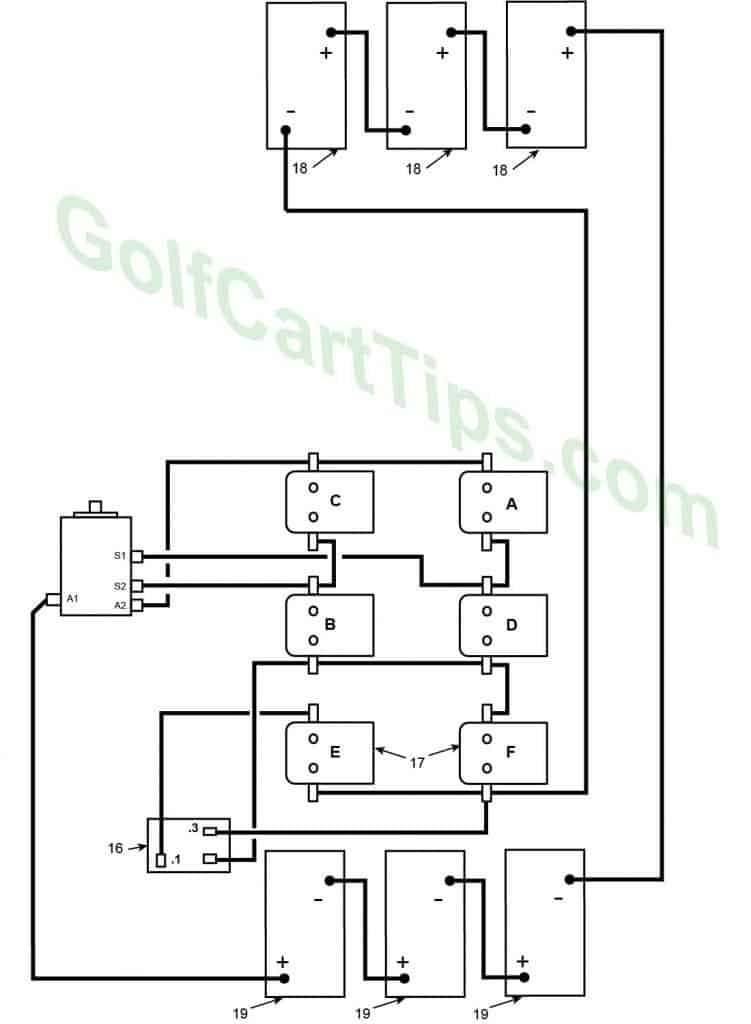

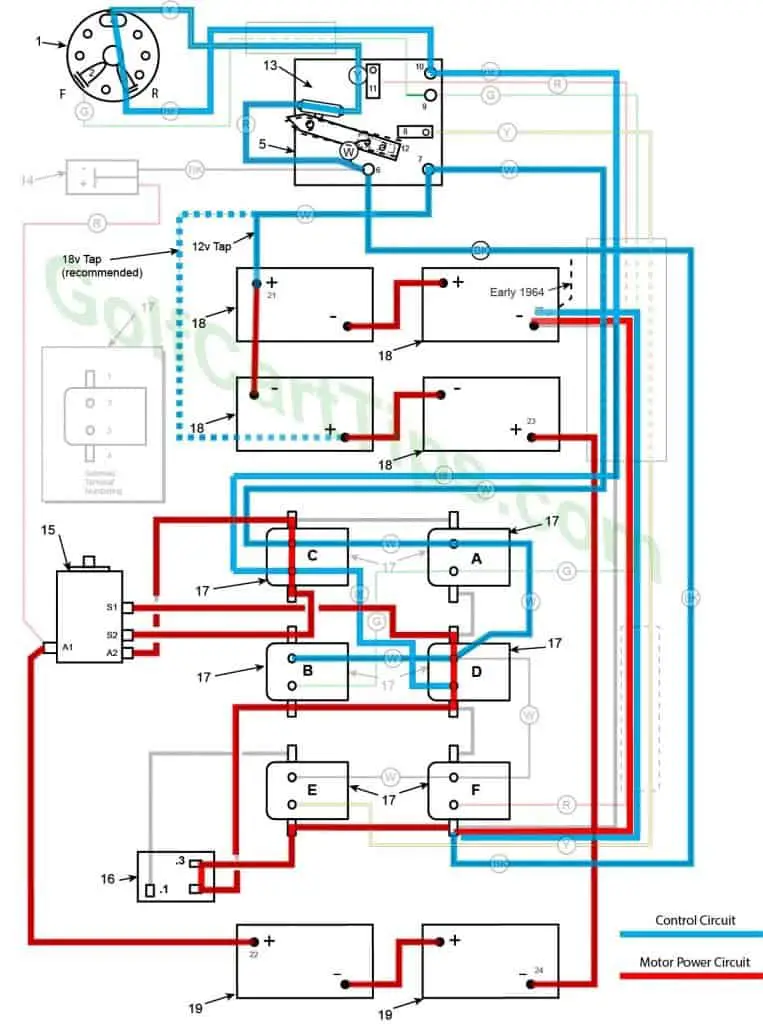

The control circuit is split up into two circuits: a 16 gauge solenoid control circuit and a heavy gauge motor circuit. The charts below separate the two for clarification.

Current to the motor from the batteries through the heavy gauge cable is controlled by the solenoids. The solenoids that connect this circuit are controlled by the lower voltage (12 or 18-volt) 16 gauge circuit which includes the key switch, the microswitch, the speed switch, and the solenoid coils. The speed of the cart is increased and decreased by selected solenoids switching through taps on a resistor.

A 12-volt tap operates the 16 gauge system and came as an original configuration on the 1963-66 carts, but the 18-volt tap (pictured in the diagram) is now recommended for more reliable operation.

The microswitch on the speed switch controls the first speed only. The second and third speed is controlled through the speed switch contactors.

What Does a Solenoid Do?

There are solenoids in both the gas models and the electric models. In the gas cart, the single solenoid engages the starter pinion gear with the “flywheel” gear on the engine, then releases after it starts. On the Electric model, a series of solenoids operate the forward and reverse functions of the electric motor and select different tap points on the resistor to change speeds.

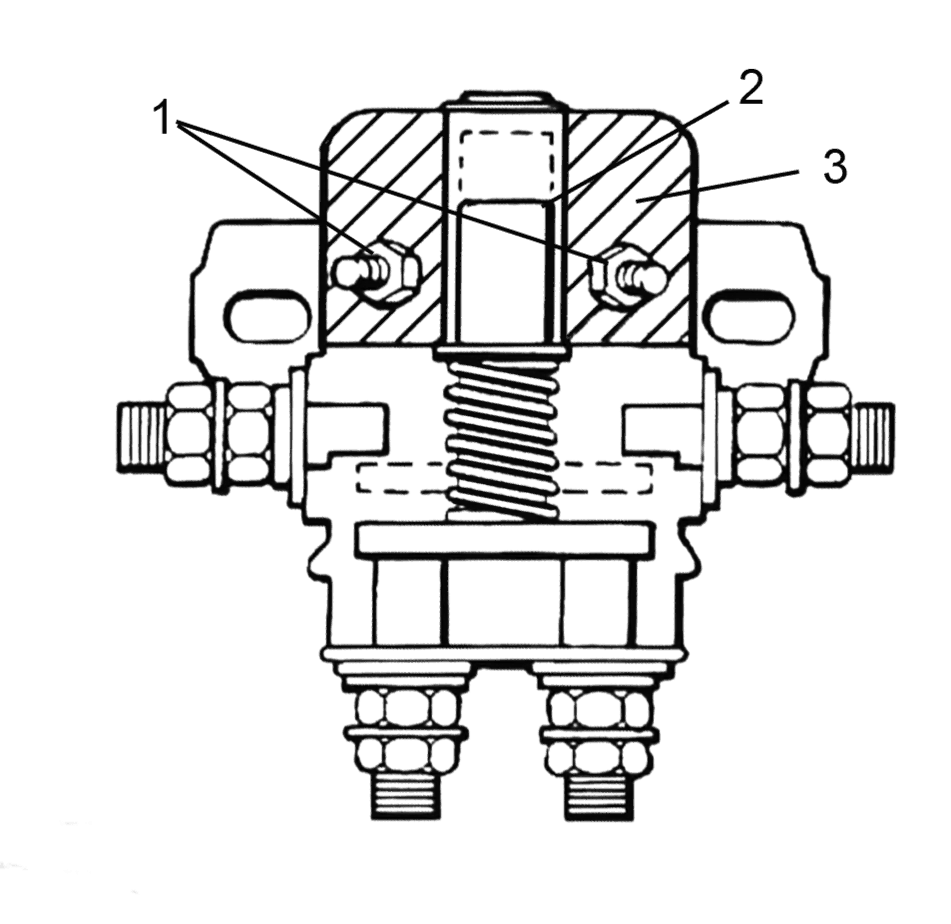

A solenoid is a switch…it is used to complete a high amperage circuit that would over-power smaller and more delicate contacts in the switch. The switch, rather than take the brunt of the snap of electricity, supplies a lower voltage to the terminals (1) which powers the electromagnetic coil (3). The magnet pulls the contact shaft up into the coil, overpowering the spring and bridging the connection (as shown by the dashed outline).

Sometimes the moving contacts get welded to the stationary blades and stay stuck in the closed-circuit mode. Other times the coil (3), which is a winding and continuous thin wire wrapping a metal core, burns out. When this happens, the moving contact stays open. Both of these situations are not repairable and the solenoid must be replaced.

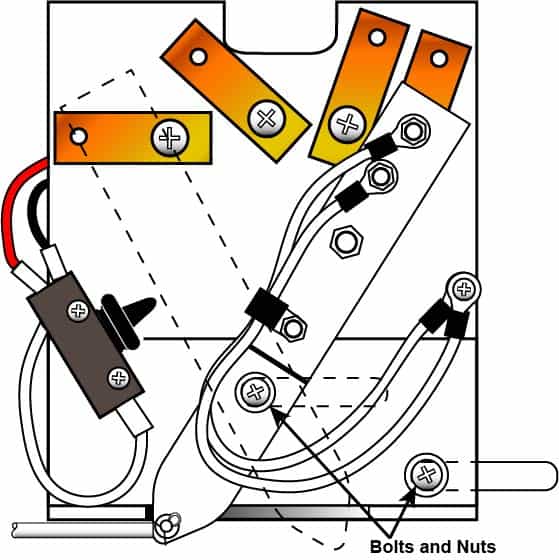

Speed Switch Adjustment

When the Speed Switch wiper arm is properly adjusted, it will be against the stop and in solid contact with the first-speed switch block, AND the foot pedal is at the rest position. When the foot pedal is fully depressed the wiper arm must have tripped the microswitch and be against the fourth contact block.

To adjust, make sure the foot pedal is at full rest and…

- Loosen the nuts on the backside of the speed switch in the locations shown on right and slide the switch assembly until the wiper arm just comes in contact with the stop.

- Tighten the nuts.

- Press the accelerator and make sure the microswitch trips. If it doesn’t quite make it to the tripped point, the pedal stop will need to be ground down until the switch can trip.

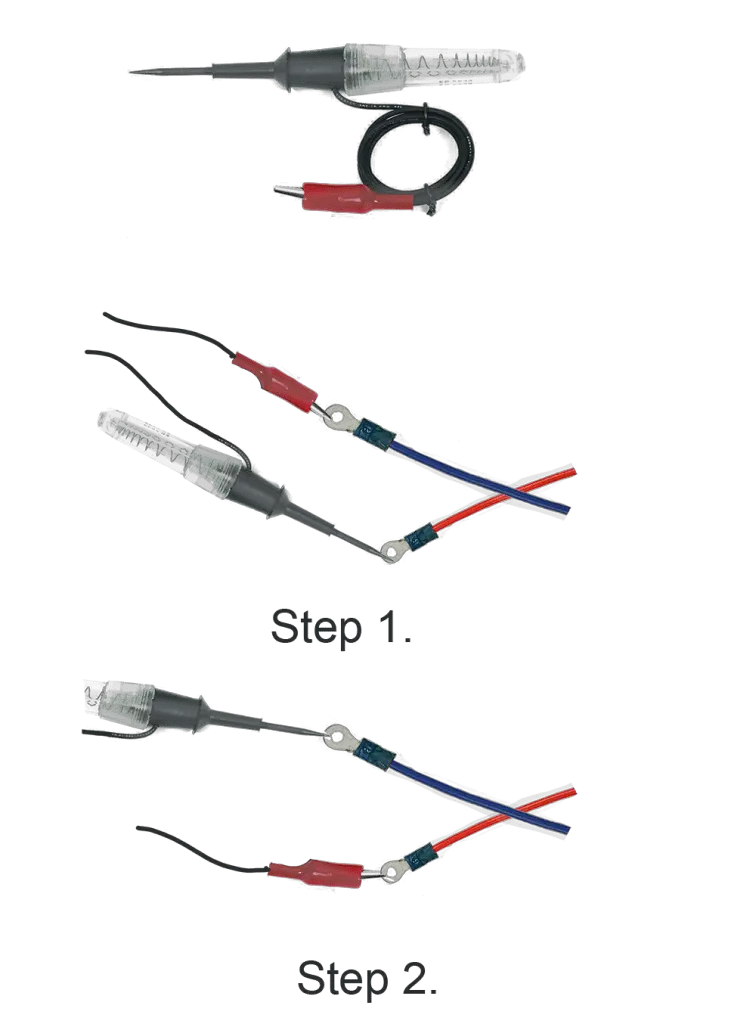

Testing Diodes

This test needs to be done with a battery-powered continuity tester. Use the continuity tester and perform step 1. The light should come on in 1.8 seconds. If the light comes on immediately or doesn’t come on at all, the unit is bad.

Perform step 2. The light should not come on at all. If it does, the unit is bad and needs to be replaced.

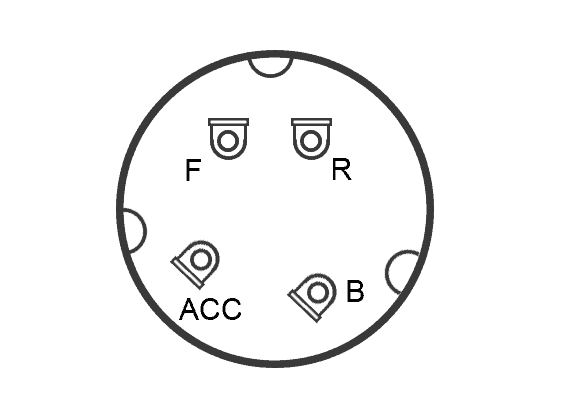

Testing the Key Switch

This test may be done with a battery-powered continuity tester or an ohmmeter set to X1.

Switch in the “OFF” position. Check for continuity between all terminals and the case of the switch. There should be no reading or continuity.

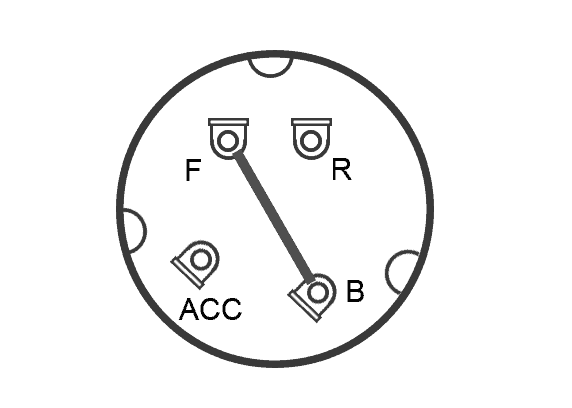

Switch in the “FORWARD” position. Check continuity between F and B terminals. There should be a reading and continuity (light on).

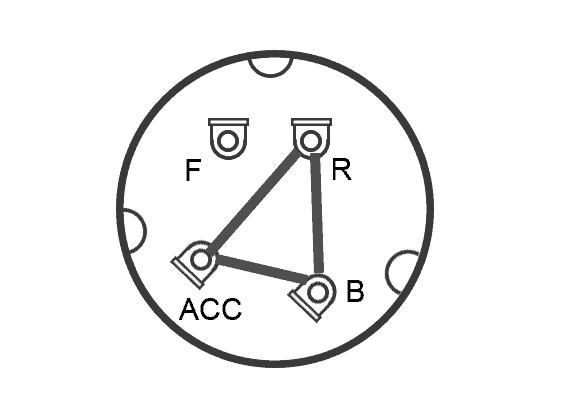

Switch in “REVERSE” position. Check continuity between R, ACC and B terminals. There should be a reading and continuity between any combination (light on).

Testing the Traction Motor

Prior to actually removing the Traction Motor from the cart, there are some in-cart tests that can be performed. These tests can be done with the continuity tester.

Motor wires A1, A2, S1, and S2 must be disconnected before testing to ensure there are no false readings from the heavy gauge motor circuit.

Motor Internal Ground Test

Connect one lead from the continuity tester to the cart frame and with the other lead, test each of the motor terminals (A1, A2, S1, and S2). The tester SHOULD NOT LIGHT. This would indicate an internal ground in the motor.

Any “Lamp On” condition with A1 or A2 indicates a possible:

- Grounded A1 or A2 terminal

- Grounded Armature/Commutator

- Grounded wire in the brush assembly

Any “Lamp On” condition with S1 or S2 indicates a possible:

- Grounded S1 or S2 terminal

- Grounded field wire

Open Field Circuit Test

Check continuity between terminals S1 and S2. The tester should light and show continuity between S1 and S2. If there is no continuity, this indicates a broken or open condition in the field.

Open Armature Circuit Test

Check continuity between terminals A1 and A2. The tester should light, showing continuity between the two terminals. If there is no continuity this indicates a possible:

- Open in the brush assembly

- Open in the armature

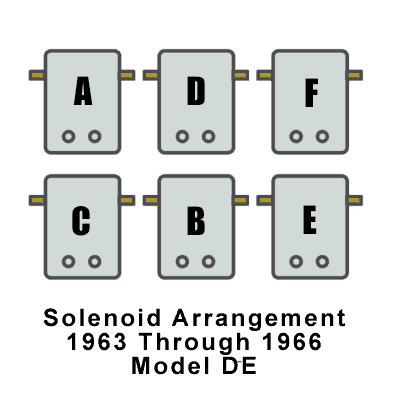

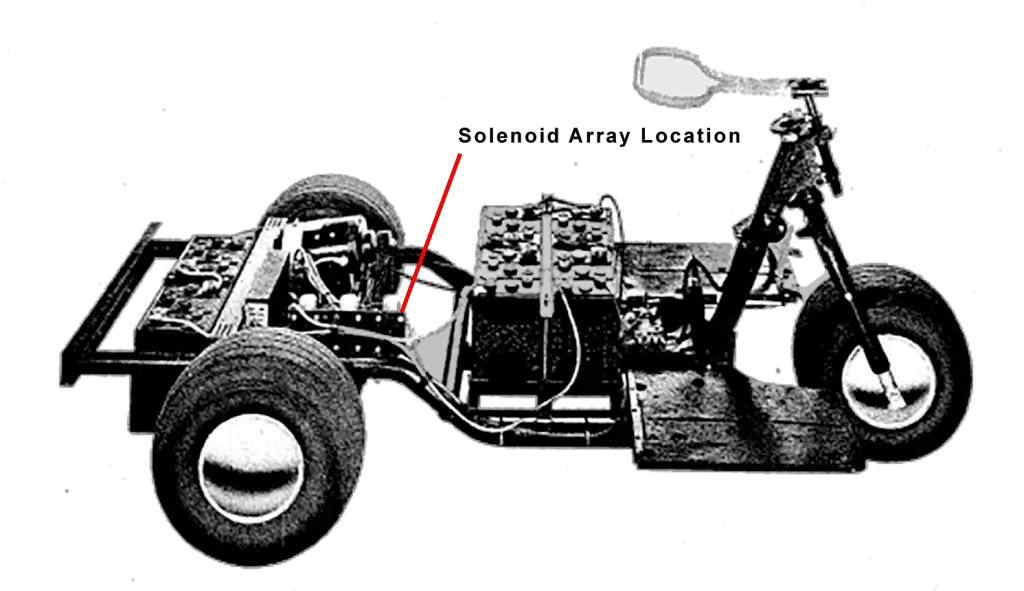

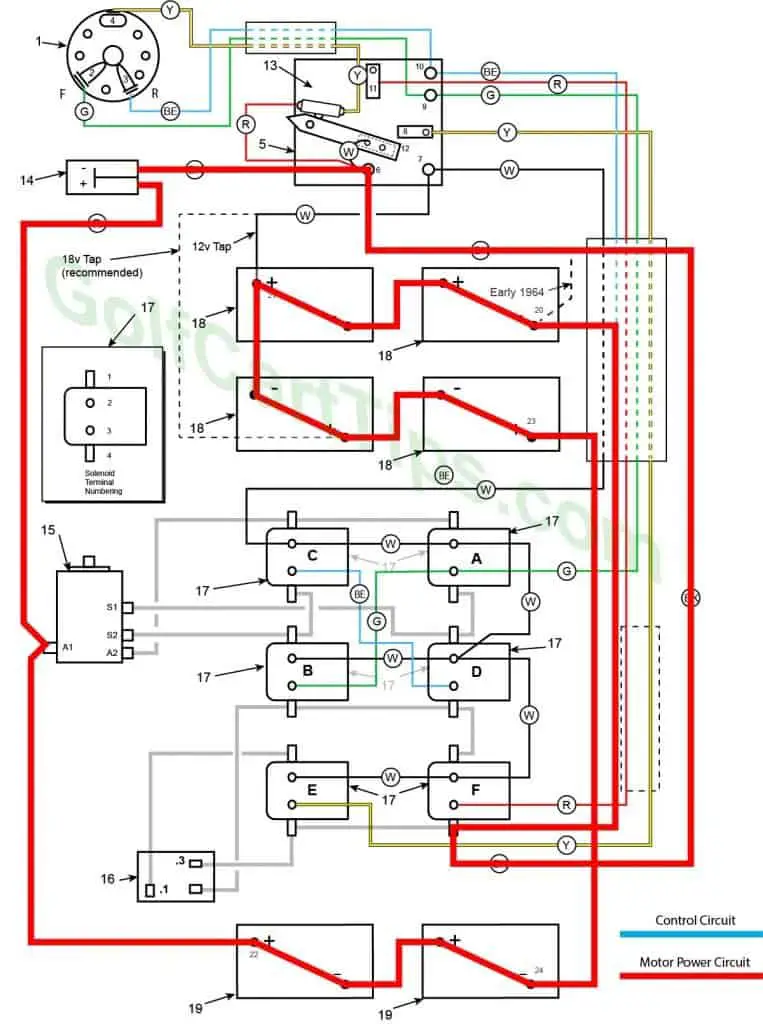

Harley Davidson Golf Cart Wiring Diagrams

1963-65 Model DE Control Circuit Wiring Diagram for 16 Gauge Wire

1963-65 Model DE Heavy Cable Diagram

The above diagram is correct for the 1963 through 1965 model DE. The 1966 model changed from a belt drive to a direct drive axle requiring the motor to rotate in the opposite direction. The key switch connections changed so that FWD becomes REV for solenoids A and B and REV becomes FWD for solenoids C and D. The battery configuration also changed to three in front and three in back.

1966 Model DE Control Circuit Wiring Diagram for 16 Gauge Wire

1966 Model DE Heavy Cable Diagram

Numbering Key for 1963 -1966 Diagrams

- Key Switch – 3 wires (Green, Blue, Yellow) For terminals 2, 3, and 4

- Key Switch Terminal – Green wire to Speed Switch Connection 9

- Key Switch Terminal – Blue wire to Speed Switch Connection 10

- Key Switch Terminal – Yellow wire to Micro Switch 13

- Speed Switch (Contains Terminals 6, 7, 8, 9, 10, 11, and 12)

- Speed Switch Terminal – White wire to Terminal 12 on Switch Arm, Red wire to Micro Switch, Black wire to Charger Plug, and Black wire to Negative Terminal on Battery (4 wires)

- Speed Switch Terminal – White wire to 12v Tap on battery, White wire to Solenoid Terminal C2

- Speed Switch Terminal – Yellow wire to Solenoid Terminal E3

- Speed Switch Terminal – Green wire to Key Switch Terminal 2 and Green wire to Solenoid Terminal A3

- Speed Switch Terminal – Blue wire to Key Switch Terminal 3 and Blue wire to Solenoid Terminal C3

- Speed Switch Terminal – Red wire to Solenoid Terminal F3

- Speed Switch Arm Terminal – White wire jumper to Speed Switch Terminal 6

- Micro Switch – Yellow wire to Key Switch Terminal 4 and Red wire to Speed Switch Terminal 6

- Charger Connection Plug – Negative Terminal 1 Black wire to Speed Switch Terminal 6 and Positive Terminal 2 Red wire to Motor Terminal A1

- Motor – 5 wires

A1 – Red wire to Charger Connection Plug Terminal 2

Black wire to Left Rear Battery Positive Terminal

A2 – Black wire to Solenoid Terminal C1

S1 – Black Wire to Solenoid Terminal D1

S2 – Black Wire to Solenoid Terminal B1 - Resistor – 3 wires

Terminal .1 – Black wire to Solenoid Terminal E1

Terminal .3 – Black wire to Solenoid Terminal E4

Unmarked Terminal – Black wire to Solenoid Terminal B4 - Solenoids A, B, C, D, E, and F

Solenoid A -Located top left (front of the cart)

A1 – Copper strap to Solenoid Terminal C1

A2 – White wire to Solenoid Terminal C2 and White wire to Solenoid Terminal D2

A3 -Green wire to Speed Switch Terminal 9 and Green wire to Solenoid Terminal B3

A4 – Copper Strap to Solenoid Terminal D1Solenoid B – Located bottom center

B1 – Copper Strap to Solenoid Terminal C4, Black wire to Motor Terminal S2

B2 – White wire to Solenoid Terminal D2

B3 – Green wire to Solenoid Terminal A3

B4 – Copper Strap to Solenoid Terminal D4, Black wire to unmarked Resistor TerminalSolenoid C – Located bottom Left (front of the cart)

C1 – Copper Strap to Solenoid Terminal A1, Black wire to Motor Terminal A2

C2 – White wire to Solenoid Terminal A2, White wire to Speed Switch Terminal 7

C3 – Blue wire to Solenoid Terminal D3, Blue wire to Speed Switch Terminal 10

C4 – Copper Strap to Solenoid Terminal B1Solenoid D – Located top center

D1 – Copper Strap to A4, Black wire to Motor Terminal S1

D2 – White wire to Solenoid Terminal F2, White wire to Solenoid Terminal B2

D3 – Blue wire to Solenoid Terminal C3

D4 – Copper Strap to Solenoid Terminal F1Copper Strap to Solenoid Terminal B4Solenoid E – Located bottom right (rear of the cart)

E1 – Black wire to Resistor Terminal .1

E2 – White wire to Solenoid Terminal F2

E3 – Yellow wire to Speed Switch Terminal 8

E4 – Copper Strap to Solenoid Terminal F4, Black wire to Resistor Terminal .3Solenoid F – Located top right (rear of the cart)

F1 – Copper Strap to Solenoid Terminal D4

F2 – White wire to Solenoid Terminal E2, White wire to Solenoid Terminal D2

F3 – Red wire to Speed Switch Terminal 11

F4 – Copper Strap to Solenoid Terminal E4, Black wire to Front Battery Negative Terminal 20, Black Wire to Speed Switch Terminal 6 (late 1964 model) - Front Batteries (4 6-volt in series with rear batteries to give a total of 36 volts. Includes tap for 12 or 18 volts for the solenoid circuit. (see the dashed area at front batteries)

- Rear Batteries

- Right Front Battery Negative Terminal – Black wire to Solenoid Terminal F4, Black wire to Speed Switch Terminal (early 1964)

- Left Front Battery Positive Terminal – 12v Tap, White wire to Speed Switch Terminal 7

- Left Rear Battery Positive Terminal @ 36v – Black wire to Motor Terminal A1

- Second Battery from Front Right Positive Terminal – Black wire to Negative Terminal Right Rear Battery

- Right Rear Battery Negative Terminal – Black wire to Terminal 23

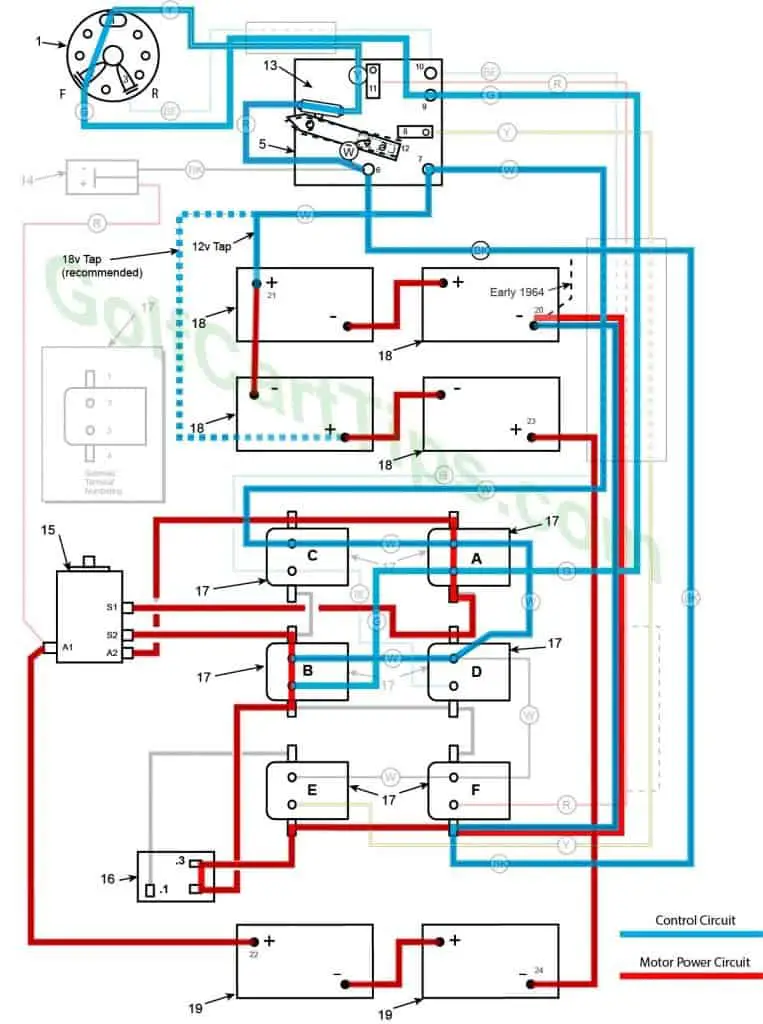

1963-66 Energized Circuits Diagrams

- Key switch – Off

- Speed Switch – at resting stop

- Solenoid “A” Open – Voltage not applied to small terminals

- Solenoid “B” Open – Voltage not applied to small terminals

- Solenoid “C” Open – Voltage not applied to small terminals

- Solenoid “D” Open – Voltage not applied to small terminals

- Solenoid “E” Open – Voltage not applied to small terminals

- Solenoid “F” Open – Voltage not applied to small terminals

- Voltage to Motor – None

- Voltage across A1 and A2 – None

- Micro Switch – Open

First Speed

- Key switch – Forward

- Speed Switch – Movement toward Second Speed Contact

- Solenoid “A” Closed – Voltage applied to small terminals, continuity across large terminals

- Solenoid “B” Closed – Voltage applied to small terminals, continuity across large terminals

- Solenoid “C” Open – Voltage not applied to small terminals

- Solenoid “D” Open – Voltage not applied to small terminals

- Solenoid “E” Open – Voltage not applied to small terminals

- Solenoid “F” Open – Voltage not applied to small terminals

- Micro Switch – Closed sending voltage to Solenoid “A” and “B” Small Terminals

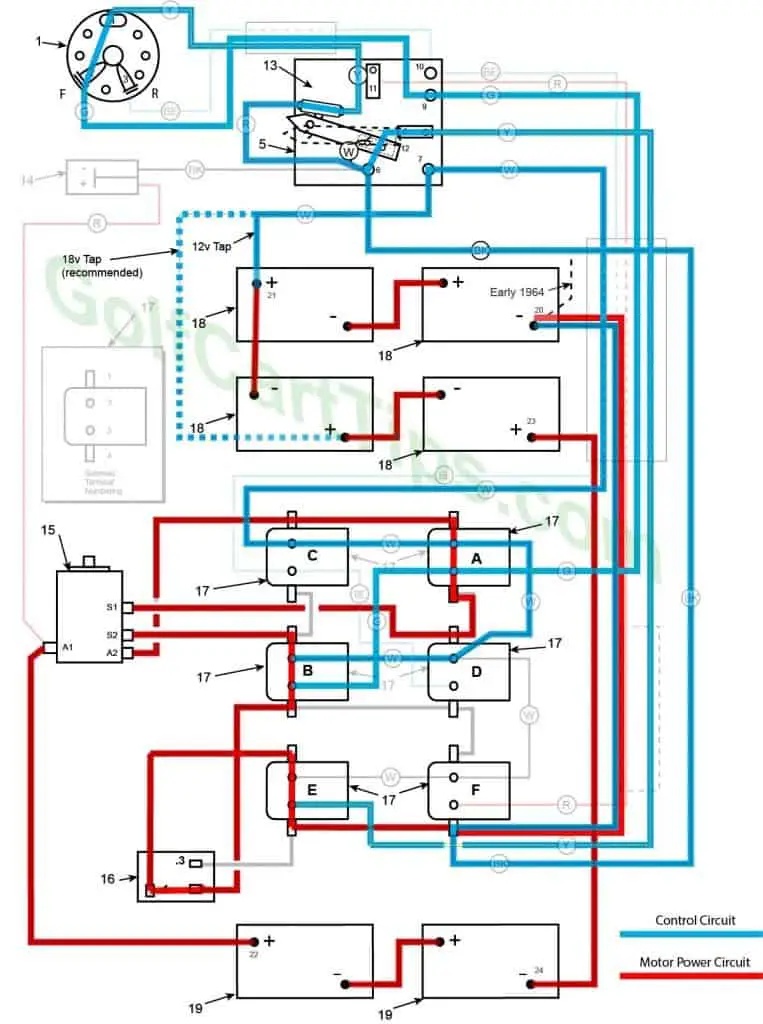

Second Speed

- Key switch – Forward

- Speed Switch – On Second Speed Contact sending voltage to Solenoid “E” small terminals

- Solenoid “A” Closed – Voltage applied to small terminals, continuity across large terminals

- Solenoid “B” Closed – Voltage applied to small terminals, continuity across large terminals

- Solenoid “C” Open – Voltage not applied to small terminals

- Solenoid “D” Open – Voltage not applied to small terminals

- Solenoid “E” Voltage applied to small terminals, continuity across large terminals

- Solenoid “F” Open – Voltage not applied to small terminals

- Micro Switch – Closed sending voltage to Solenoid “A” and “B” Small Terminals

Third Speed

- Key switch – Forward

- Speed Switch – On Third Speed Contact sending voltage to Solenoid “F” small terminals

- Solenoid “A” Closed – Voltage applied to small terminals, continuity across large terminals

- Solenoid “B” Closed – Voltage applied to small terminals, continuity across large terminals

- Solenoid “C” Open – Voltage not applied to small terminals

- Solenoid “D” Open – Voltage not applied to small terminals

- Solenoid “E” Open – Voltage not applied to small terminals

- Solenoid “F” Voltage applied to small terminals, continuity across large terminals

- Micro Switch – Closed sending voltage to Solenoid “A” and “B” Small terminals

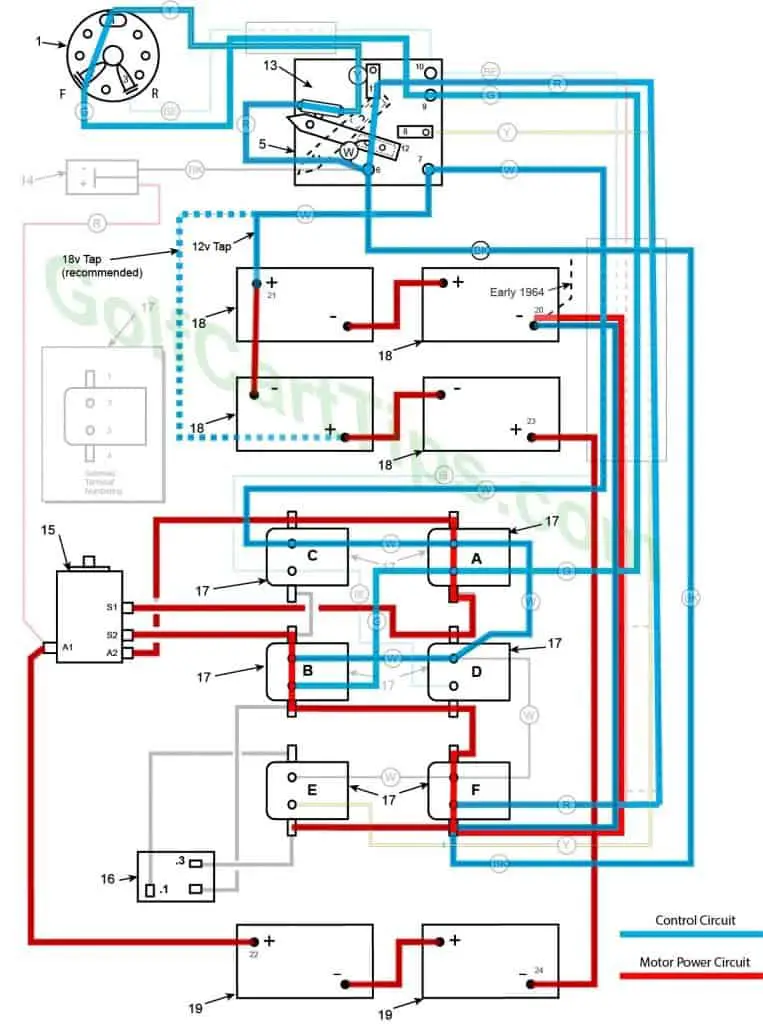

Reverse (First Speed Only Shown)

- Key switch – Reverse

- Speed Switch – Same as Forward Speeds

- Solenoid “A” – Open – Voltage not applied to small terminals

- Solenoid “B” – Open – Voltage not applied to small terminals

- Solenoid “C” – Voltage applied to small terminals, continuity across large terminals

- Solenoid “D” – Voltage applied to small terminals, continuity across large terminals

- Solenoid “E” – Same as Forward Speeds

- Solenoid “F” – Same as Forward Speeds

- Micro Switch – Same as Forward Speeds

1963 Through 1966 Models DE and DEC Troubleshooting Chart

| Symptom | Possible Cause | Remedy |

|---|---|---|

| Batteries Run Down Rapidly | ||

| Batteries not charging fully | Bad Battery | Test battery cells |

| Low Electrolyte Level | Refill cells with electrolyte | |

| Bad Charging Circuit | Inspect terminals and connections for looseness and corrosion | |

| Bad Charger | Use multimeter and test output voltage | |

| Battery Drain other than use | Corrosion | Inspect battery and speed switch contacts and clean where needed |

| Loose Connections | Tighten all terminals and connections | |

| Shorts in the Circuit | Check for frayed wires touching other terminals or debris shorting contacts | |

| Faulty Motor | Go through the motor testing procedures | |

| Drag or Resistance | Brakes tight | Adjust brakes |

| Low Tire Pressure | Fill tires to recommended pressure | |

| Wheel Bearings Dragging | Lubricate wheel bearings or replace if bad | |

| Incorrect Drive Belt Tension (63-65) | Adjust belt tension | |

| Differential Dragging | Check lubrication on differential and chassis | |

| Overloading | Verify carts carrying capacity is not exceeded | |

| Driving with foot on the brake | Don’t…this will wear out the brakes prematurely as well. | |

| Slipping Drive Belt (63-65) | Drive Belt Out of Adjustment | Adjust belt tension |

| Cart Will Not Operate Forward or Reverse | ||

| Batteries Discharged | Check if charger is operating properly and charge batteries | |

| Speed Switch Failure or Linkage disconnected | Check the operation of the foot pedal moving the switch arm and test speed switch | |

| Key Switch Bad | Use continuity tester and replace if faulty | |

| Solenoids inoperative | Listen for solenoid clicks, and if no sound check wiring to terminals. Check solenoids with testing procedure. | |

| Micro Switch inoperable | Use multimeter to test micro switch operation | |

| Drive Belt Not Engaged | Adjust belt tension | |

| Motor Fault | Check brushes and armature, run motor test procedure | |

| Corroded Battery Terminals | Check and clean battery posts and connections | |

| Faulty Wiring Circuit | Using the wiring diagram for your model, trace out and correct any loose or broken connections | |

| Car Operates Forward, Not in Reverse | ||

| Reverse Solenoids C and/or D Inoperable | Use testing procedure on solenoids C and D | |

| Forward Solenoids A and/or B staying Closed | Use testing procedure on solenoids A and B | |

| Wiring Broken or Defective | Using the wiring guide, test wiring to electrical components | |

| Bad Key Switch | Using a continuity tester, perform continuity test on key switch terminals | |

| Car Operates in Reverse, Not in Forward | ||

| Forward Solenoids A and/or B Inoperable | Use testing procedure on solenoids A and B | |

| Reverse Solenoids C and/or D staying closed | Use testing procedure on solenoids C and D | |

| Wiring Broken or Defective | Using the wiring guide, test wiring to electrical components | |

| Bad Key Switch | Using a continuity tester, perform continuity test on key switch terminals | |

| Car Leaps or Jerks | ||

| Solenoids Sticking or Hanging | Use testing procedure on solenoid | |

| Faulty Resistor | Check resistor for breaks and check taps and connections | |

| Loose or Corroded Connections | Clean and tighten connections | |

| Cart Only Runs in First Speed | ||

| Second Speed Solenoid E and Third Speed Solenoid F Faulty | Use testing procedure on solenoid | |

| Faulty Wiring | Check connections and continuity from speed switch to solenoids | |

| Cart Runs in First and Third Speed, Not in Second Speed | ||

| Solenoid E Faulty | Use testing procedure on solenoid | |

| Faulty Wiring | Check connections and continuity from speed switch to solenoids | |

| Cart Runs in First and Second Speeds, Not in Third Speed | ||

| Solenoid F Faulty | Use testing procedure on solenoid | |

| Contacts on Speed Switch and on Third Speed not making a good contact | Check and clean contacts on speed switch | |

| Faulty Wiring | Check for open circuit, shorts, or loose connections | |

| Cart Will Run in Second and Third Speed, Not in First | ||

| Resistor open between .1 and .3 terminals | Check continuity on resistor and connections | |

| Faulty Wiring | Check connections and continuity from speed switch to solenoids | |

| Cart Will Not Run in First or Second Speeds, Only Third | ||

| .1 Ohm Section of Resistor between .1 and unmarked terminals open or both sections open | Use continuity tester on resistor terminals | |

| Faulty Wiring | Check continuity from resistor common terminal to solenoid | |

| Cart Runs in First Speed Then Jumps to Third Speed | ||

| Faulty Wiring | Check continuity of red and yellow wires from speed switch to solenoids | |

| Solenoid E Faulty | Use testing procedure on solenoid | |

| Cart Goes to Third Speed Immediately When Pedal is Pressed | ||

| Third Speed Solenoid F Stuck Closed | Use testing procedure on solenoid | |

| Faulty Wiring | Check wiring continuity fo blue and red wires from speed switch to solenoids | |

| Cart Goes to Second Speed Immediately When Pedal is Pressed, Third Speed Normal | ||

| Second Speed Solenoid E Stuck Closed | Use testing procedure on solenoid | |

| Faulty Wiring | Check wiring continuity from speed switch to solenoids | |

| Cart Starts Forward When Key Switches On | ||

| Speed Switch Stuck | Check speed switch | |

| Cart Does Not Stop With Key On | ||

| Speed Switch Arm Not Returning to Off Position | Check speed switch, return spring and linkage | |

| Cart Does Not Stop With Key Off | ||

| Key Switch Faulty or Shorted | Inspect key switch and test with continuity tester | |

Conclusion

These charts and illustrations are to be used in aiding the repair and maintenance of your Harley Davidson golf cart. The illustrations and language will be updated and more details become available. Many of the parts for these models can be found at Vintage Golf Cart Parts.

Other Years and Models for The Harley Davidson Golf Cart